Description

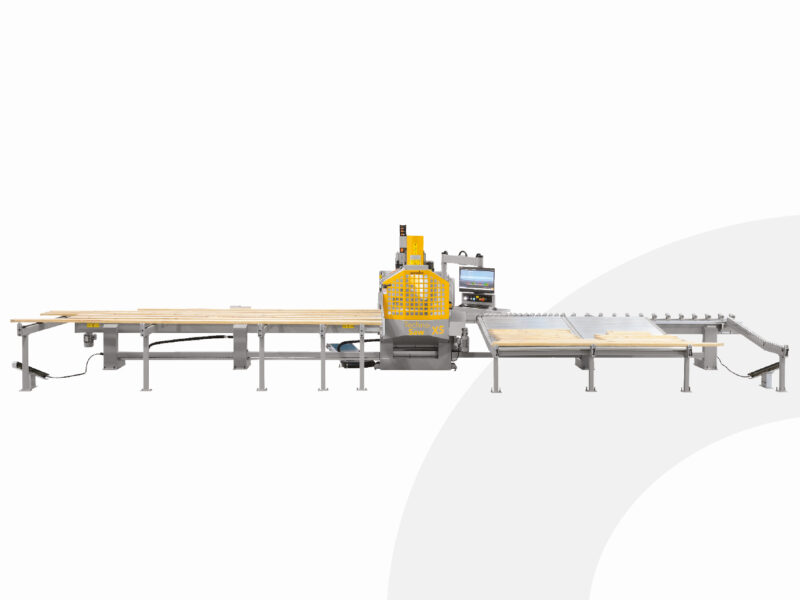

Working area.

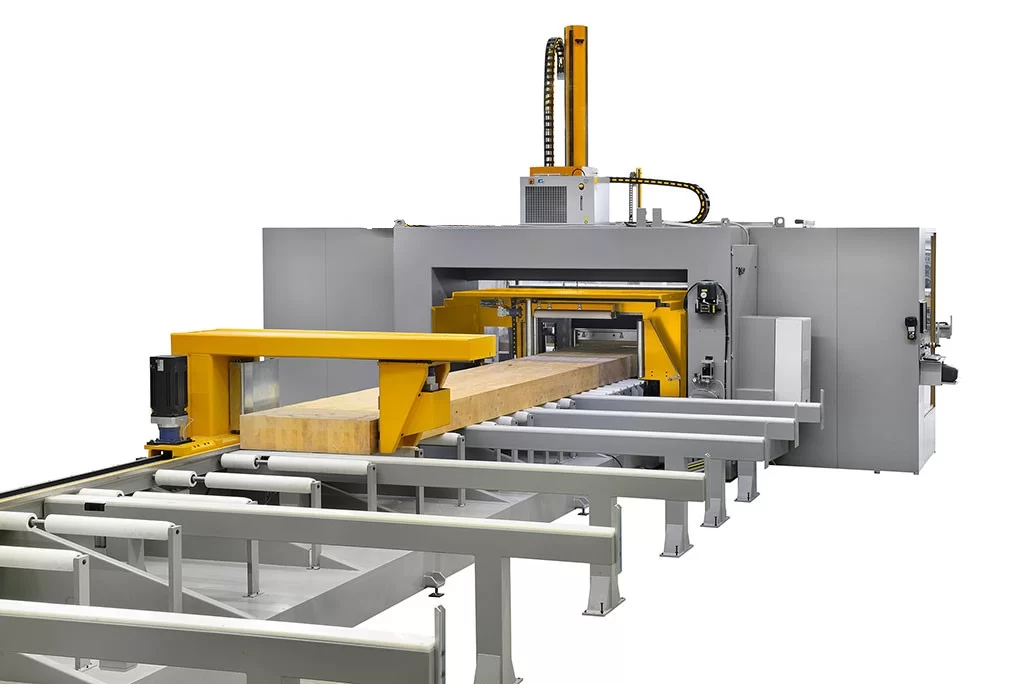

Patented milling head with 5 continuous interpolating axis for the processing of the 6 faces of the workpiece. Patented dual output motor with HSK63F tool holder.

Infeed handling system.

Parts are pre-loaded by a NC automatic clamp; a second CNC clamp will check the correct section and ensure precise position of the part to be processed.

Loading area.

Large pre-loading area, designed to load one or more pieces with a maximum width of 1300 mm, which will then be managed by the infeed clamps.

Outfeed handling system.

It consists of an automatic clamp managed by the NC, which allows the workpiece to be moved from the cabin to the exit zone for successive evacuation and storage in the unloading area. A second clamp is also installed in the unloading area to handle the part during processing.

Console.

A control console complete with NC is installed on the machine structure using a hinge system, allowing it to be oriented in multiple positions.

A remote control panel is available complete with manual controls of the axis movement, START, STOP and RESET of the program.

An automatic printer interfacing with the NC generates the labels during unloading.

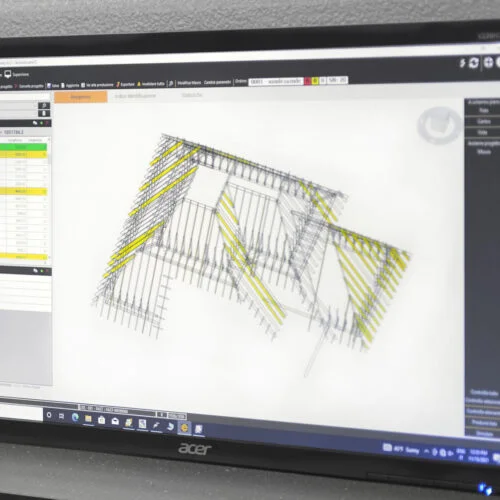

E-live software.

The machine is controlled by the new Essetre E-Live Software, with three-dimensional display of the workpiece and relative processing. Its versatility allows it to interface with the most well-known Cad Cam programs specific for wooden structures.

The software is also equipped with a simulation and anti-collision system.