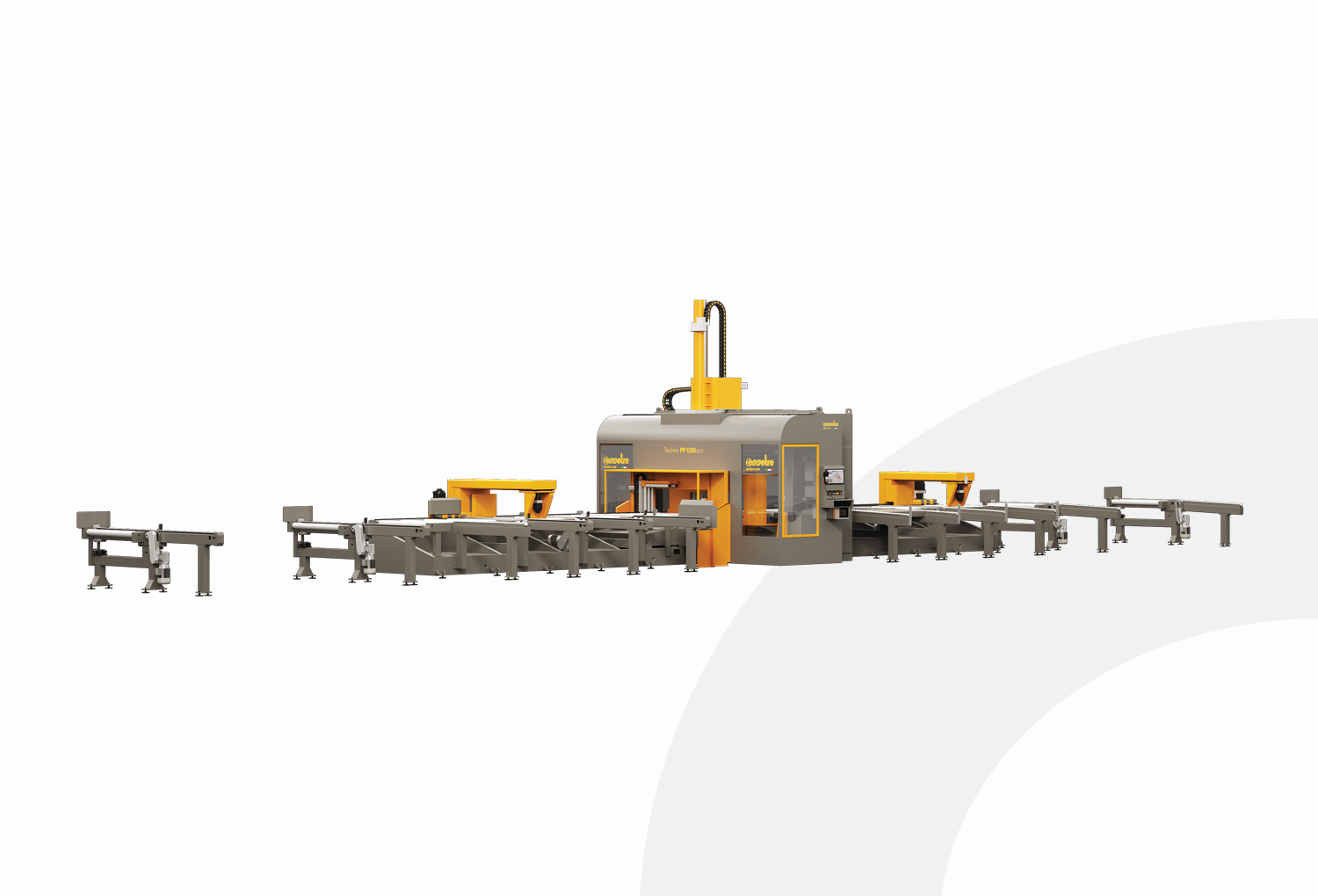

LVL CNC Machines: Precision Laminated Veneer Lumber Fabrication.

Advanced 5-axis CNC systems engineered for LVL beam fabrication and engineered lumber processing.

Transform your LVL production with Italian precision engineering designed for American engineered lumber manufacturing and construction.

Advanced LVL Manufacturing for American Construction.

Laminated Veneer Lumber (LVL) represents the evolution of engineered wood products in American construction. From residential floor systems to commercial long-span applications, LVL beams require precision machining capabilities that maximize the engineered performance characteristics while maintaining dimensional stability and structural integrity.

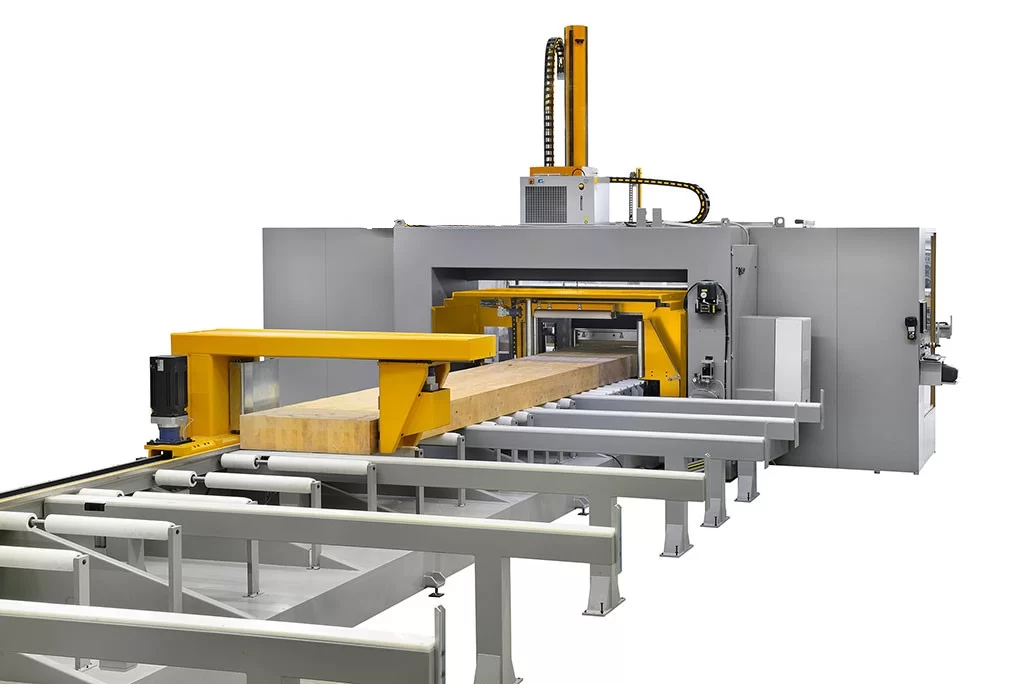

Essetre NA’s specialized LVL CNC machines handle beams with standard dimension 45 feet in length, providing the accuracy and flexibility required for complex engineered connections, custom beam fabrication, and hybrid construction systems. Our 5-axis CNC systems perform precise notching, drilling patterns, connection recesses, and custom beam shaping with tolerances that ensure perfect structural performance.

Unlike general-purpose lumber processing or conventional beam equipment, our engineered lumber CNC routers are designed specifically for LVL beam processing, supporting everything from residential floor systems to commercial structural applications. Whether you’re producing beams for multi-family construction, commercial buildings, or specialty engineered applications, our Italian-engineered systems deliver the precision and efficiency that American LVL manufacturers demand.

Essetre NA’s specialized CLT CNC machines handle panels up to 12 feet wide and 60 feet long, providing the accuracy and efficiency required for modern CLT manufacturing. Our 5-axis CNC systems perform complex edge profiling, opening cuts, connection details, and surface texturing with tolerances that ensure perfect panel fit in the field. Unlike general-purpose woodworking equipment, our large-format CNC routers are engineered specifically for CLT panel processing, integrating seamlessly with North American BIM workflows and supporting the rapid growth of CLT construction across the United States. Whether you’re producing panels for multi-story buildings or custom architectural projects, our Italian-engineered systems deliver the reliability and precision that CLT manufacturers demand.

LVL Processing Capabilities.

Engineered Connection Systems.

Master modern engineered connections with CNC precision designed for LVL’s unique structural properties. Our systems create connections that maximize LVL’s engineered strength while ensuring proper load transfer and structural performance.

Engineered Connection Capabilities:

Joist hanger notches

with precise dimensional control for uniform bearing

Beam pocket connections

for ledger and rim beam applications

Engineered fastener patterns

optimized for LVL fiber orientation

Hybrid connection systems

for LVL-to-steel and LVL-to-concrete interfaces

Custom connection details

for engineered structural applications

Precision Beam Fabrication.

Shape engineered LVL beams with precision control optimized for laminated veneer lumber’s directional strength properties and manufacturing characteristics.

Fabrication Capabilities:

Dimensional beam cutting

with fiber-optimized cutting strategies

Multi-depth notching

for floor system integration

Taper cuts

and custom profiles for architectural applications

Bearing seat preparation

with precise dimensional control

End treatment

and connection preparation for optimal performance

Dovetailing

Floor System Integration.

Process LVL components for complete floor systems including rim beams, joists, and specialty members designed for modern residential and commercial construction methods.

Floor System Processing:

Rim beam fabrication

with precise pocket cuts and connection details

Joist processing

with web openings and service penetrations

Bearing point preparation

for optimal load distribution

Cantilever detailing

for balcony and overhang applications

High-Volume Production.

Execute efficient production operations optimized for LVL manufacturing including automated handling, quality control, and production line integration.

Production Operations:

Automated beam handling

for continuous production flow

Quality control drilling

for grade verification and identification

Production marking

and labeling systems

Dimensional verification

with integrated measurement systems

Packaging preparation

with stacking and bundling optimization

Technical Specifications for LVL Fabrication.

Machine Configuration.

Working dimensions:

standard 45 feet L × 4 feet W × 3 inches H

5-axis simultaneous machining

for complex connection geometries

LVL capacity:

Up to 8,000 lbs with specialized handling systems

High-speed spindle configurations

for engineered lumber processing

Vacuum hold-down systems

designed for laminated product stability

LVL-Specific Features.

Fiber-sensitive cutting strategies

optimized for veneer orientation

Specialized tooling

designed for laminated product characteristics

Automated quality verification

for engineered lumber standards

Production line integration

for continuous manufacturing flow

Environmental controls

for dimensional stability during processing

Software Integration

Engineered lumber CAD integration

with structural design software like Cadwork, HSB, Dietrich’s, Sema, Revit and more

Connection optimization

based on LVL span tables and load requirements

Production scheduling

for high-volume manufacturing

Quality tracking

and documentation systems

Material optimization

for waste reduction

LVL Construction Applications.

Residential Floor Systems.

Precision LVL processing for residential floor framing, including single-family, multi-family, and custom home applications where engineered performance meets construction efficiency.

Applications: Single-family homes, townhomes, apartments, condominiums, custom residences

Key Benefits: Superior span capability, dimensional stability, reduced callbacks and warranty issues.

Commercial Structural Systems.

Engineered LVL beams for commercial buildings, office structures, and institutional projects requiring long clear spans and predictable structural performance.

Project Types: Office buildings, retail structures, schools, healthcare facilities, mixed-use developments

Advantages: Consistent material properties, architectural flexibility, code compliance assurance.

Multi-Family Construction.

High-volume LVL processing for multi-family developments, apartment buildings, and housing projects requiring efficient construction methods and reliable performance.

Facilities: Apartment complexes, student housing, senior living, affordable housing, mixed-use developments

Benefits: Construction speed, material consistency, reduced field labor requirements.

Specialty Engineered Applications.

Custom LVL fabrication for unique structural applications including hybrid systems, specialty connections, and innovative construction methods showcasing LVL versatility.

Applications: Hybrid timber-steel systems, seismic applications, high-performance buildings, specialty structures.

LVL Manufacturing Advantages.

Engineered Performance Optimization.

Computer-controlled processing ensures optimal utilization of LVL’s engineered properties while maintaining dimensional accuracy and connection integrity for superior structural performance.

Impact: Maximized span capabilities, eliminated field modifications, superior load performance.

High-Volume Production Efficiency.

Automated processing systems enable efficient LVL production while maintaining quality control and dimensional consistency required for modern construction schedules.

Capacity: 10X increase in beam processing vs. conventional methods, consistent quality at production scale

Complex Connection Capability.

5-axis machining handles any engineered connection configuration including compound angles, multiple bearing seats, and hybrid connection systems impossible with conventional equipment.

Results: Complete connection flexibility, optimized structural performance, unlimited design integration.

Material Waste Reduction.

Advanced optimization algorithms maximize utilization of LVL stock lengths, reduce waste, and support sustainable manufacturing practices in engineered lumber production.

Environmental Benefits: Waste reduction, optimized material usage, sustainable forestry support.

Frequently Asked Questions.

What LVL beam sizes can your CNC machines process?

Our LVL CNC systems can process beams standard dimension 45 feet in length with width 48” and thickness 24“. We can configure systems for specific LVL dimensions and handle both standard and custom LVL beam sizes based on your production requirements.

Can your systems handle high-volume LVL production?

Absolutely. Our systems are designed for high-volume engineered lumber production with automated handling, continuous processing capabilities, and integrated quality control. We can process hundreds of beams per day while maintaining consistent quality and dimensional accuracy.

Do your systems integrate with structural engineering software?

Yes, we provide seamless integration with major structural design platforms. Our systems can directly import beam schedules and automatically generate optimized toolpaths for all connections and details based on engineering specifications.

What connection types can you machine in LVL beams?

Our LVL CNC systems can machine any engineered connection detail including joist hanger seats, beam pockets, bolt patterns, steel connection recesses, and custom connection geometries. We maintain libraries for all major connection hardware manufacturers.

Can you process LVL for floor system applications?

Yes, our systems excel at complete floor system fabrication including rim beams with precise pocket cuts, joists with web openings, and all connection details required for modern floor framing systems. We can process complete floor packages with optimized material utilization.